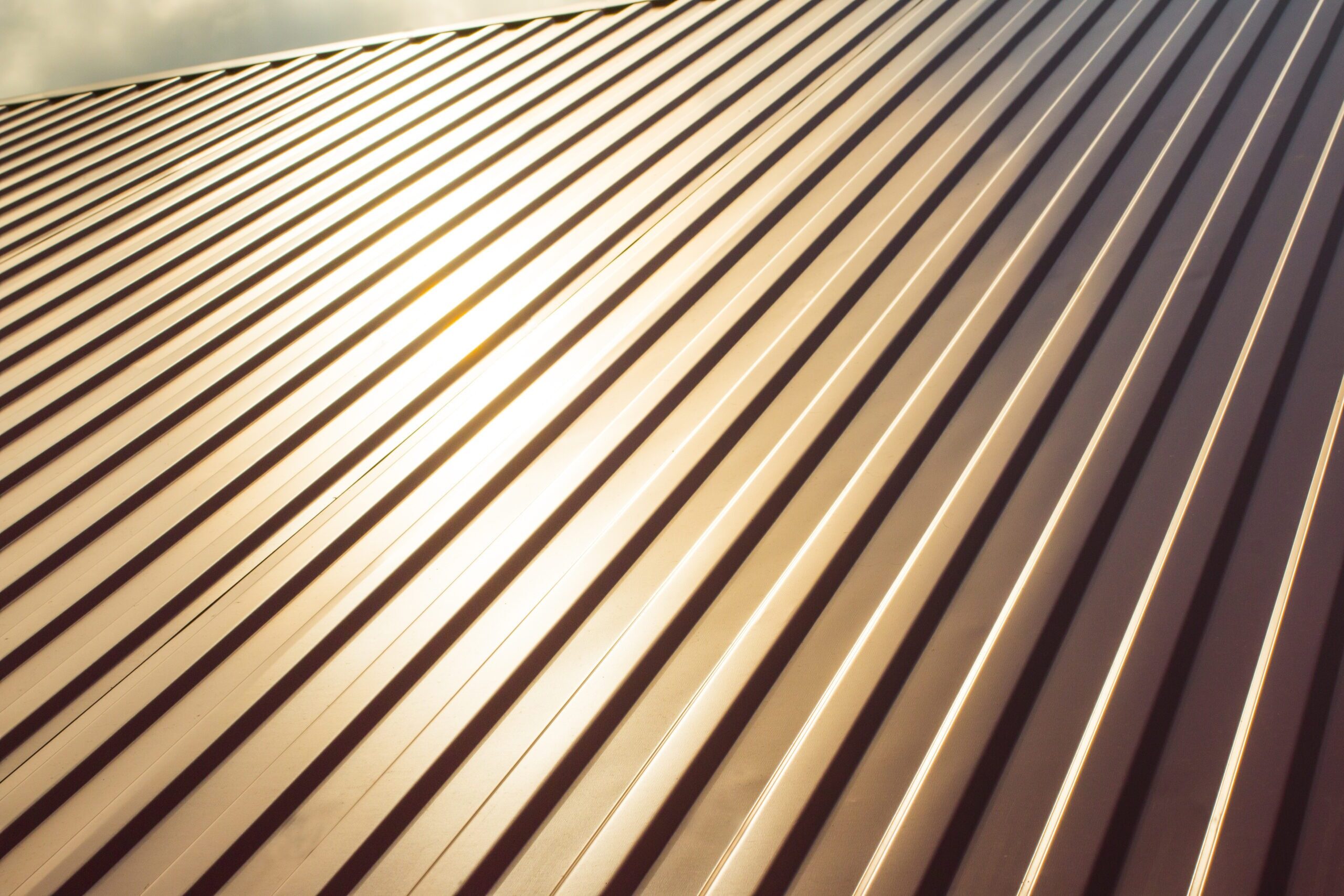

Sheet metal roof waterproofing

We offer innovative and sustainable waterproofing for for sheet metal roofs of all types.

New construction, renovation & planning

Sheet metal roof waterproofing with polyurea

Sheet metal roofs are exposed to the highest loads and must withstand all weathers. Conventional waterproofing fails after a few years and the consequential damage is extensive.

Polyurea sheet metal roof waterproofing was developed for this purpose. It is all-weather resistant, cures quickly and provides lasting protection for any tin roof for decades. Both in new construction and renovation.

Offer

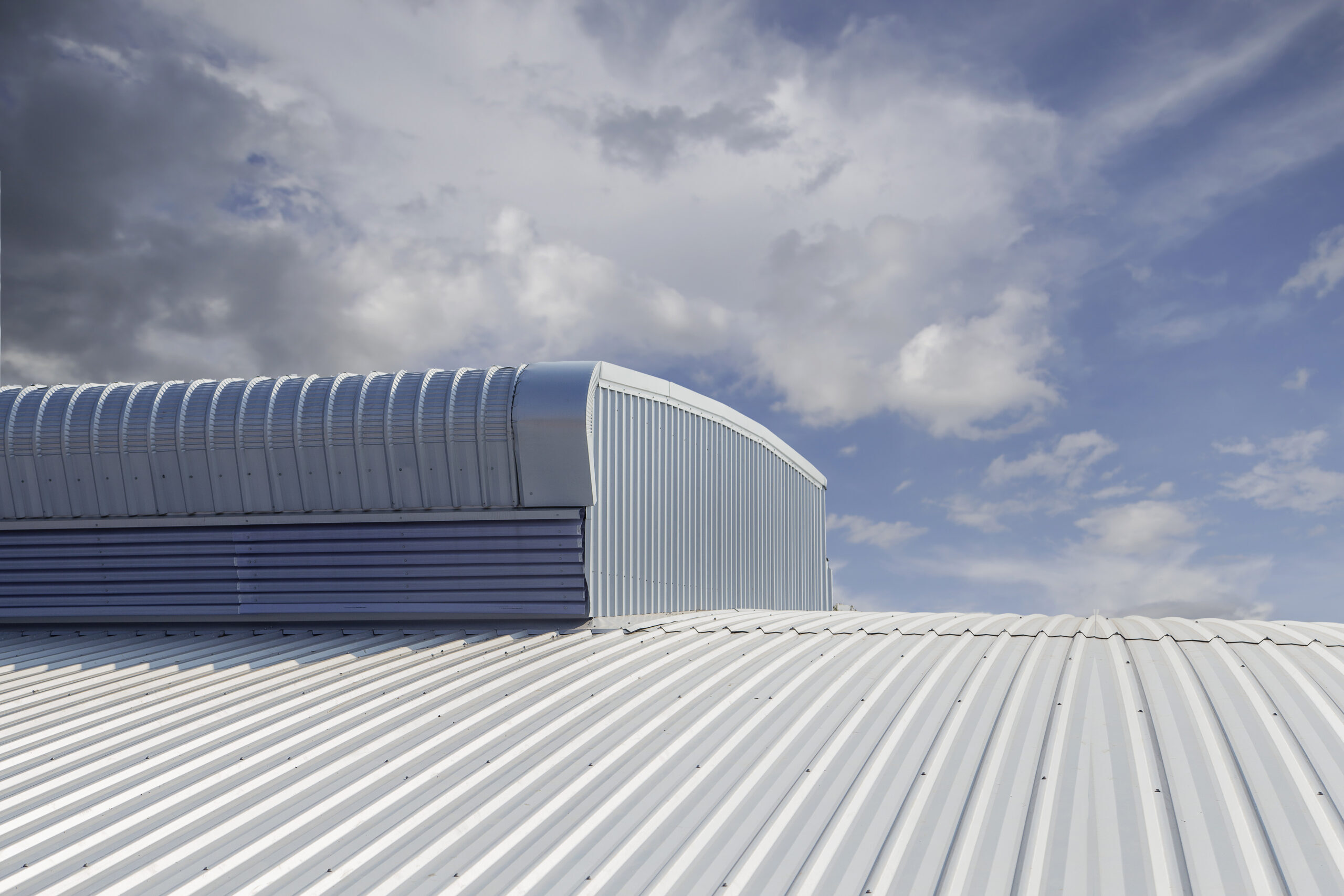

Our offer ranges from new construction to renovation and complete ref urbishment of sheet metal roofs of various types.

Redevelopment

Renovation and maintenance are particularly important to ensure the functionality of the Eternit roof. Polyurea is the best renovation solution due to its high flexibility and durability.

New construction

We seal newly built eternit roofs of all types. Both residential and commercial large roofs with complex surface can be waterproofed with polyurea.

consulting

We will be happy to advise you on a wide variety of concerns regarding your Eternit roof waterproofing. Simply submit a request below via phone or contact form.

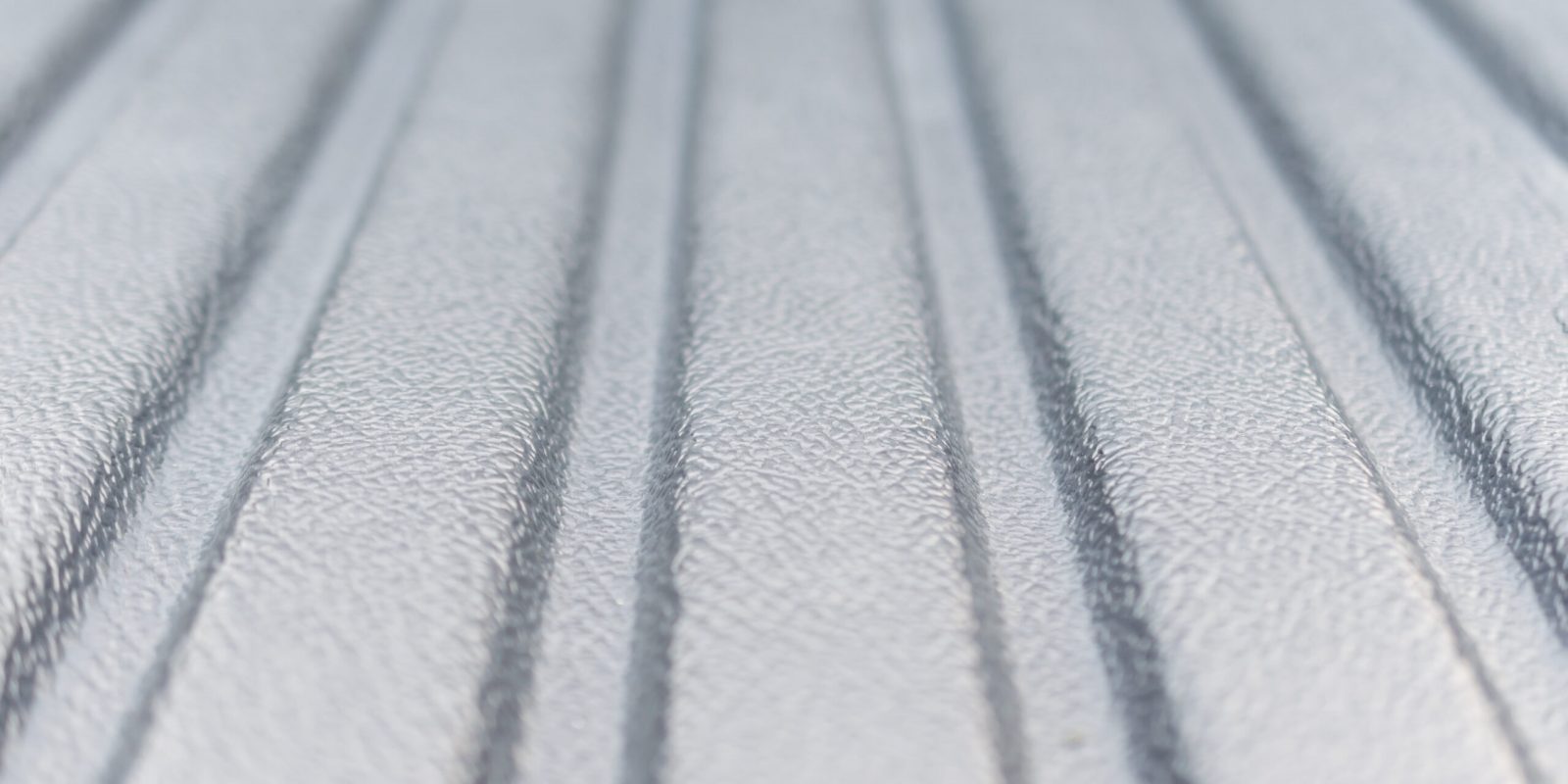

Advantages

A brief overview of the main advantages of a polyurea spray film for eternit roof coating.

all-weather

Eternit roofs are exposed to a wide range of climatic & weather conditions in Central Europe. Polyurea is resistant to heat, frost, hail, wind and snow.

Fast application

After the substrate has been pre-treated, the primer and spray application is carried out using polyurea, which reaches final hardness after 3 seconds.

long service life

Buildings & real estate should last for generations and for that you need the right roof. Polyurea impresses with its extremely long service life.

All geometries

100% Dense

All-weather

UV Stable

Standard tin roof vs. Polyurea solution

Leaking

With most films, the first water damage occurs after just a few years due to leaks.

cracks

Often, the temperature differences cause slight cracks. Water ingress is the result.

discoloration

Color changes reduce the well-being, aesthetics and appearance of the architecture.

Hydrolysis resistant

Polyurea does not allow osmosis or water to pass through. The coating system is always preserved and functional.

Flexible

Due to its high flexibility, the jointless seal also protects against cracks. (e.g. by expansion)

All-weather

The top coat is possible in any RAL tone , color resistant & all weather resistant.

QUESTIONS & ANSWERS

for further questions just call or contact us by email

In principle, any sheet metal roof is suitable for coating with polyurea. These include, but are not limited to:

- Corrugated iron

- Sheet metal seam roof

- Flat roof

- Pitched roof

- Private roof

- Industrial area

- uvm.

The advantages of a polyurea coating lie primarily in its resilience, flexibility and durability. In addition, the seamless surface can be sealed with all RAL shades.

Basically, we manage to prime, coat and fully seal around 250m2 / day. The curing time is a few seconds. Thus, the application is quick and fast.

Our minimum guarantee is 25 years. However, polyurea has been shown in practice to outlast decades.

Since we use the product in cooperation with the company BASF, there is every conceivable technical detail about Polyurea. You can find all information

here

.

The m2 price or the total cost depends strongly on the total area as well as the substrate. Simply fill in all the information below and get a free quote.

reference gallery

Polyurea is suitable for both new waterproofing and renovation of sheet metal roofs of various types.